- Assessment: Financial Performance Evaluation of Savory Snacks Company Ltd for Credit

- CMI L5 Assignment: Managing Stakeholder Relationships: Strategies, Challenges, and Best Practices

- Level 3 Unit 2 Assignment: Principles, Values and Regulation in the Health and Social Care Sector

- COM4006 Assignment: Introduction to Academic Skills and Professional Development

- Assessment: Managing Organisational Change: Evaluating Strategies, Challenges, and Impact

- UNIT CMI 706 Assignment: Finance for Strategic Leaders: The Role, Scope, and Impact of Finance

- ENGINEERING DESIGN TMA2 v1: CAD Design Report: Specification, Evaluation & Drawings

- Unit CMI 514 Assignment: Analysis of Organisational Change: Managing Change

- EMS402U TMA1: Engineering Design Solutions: Concept Development & Assessment

- LEVEL 3 UNIT 31: Effective Project Management (International BTEC )

- ILM Level 4 ASSIGNMENT: Managing equality and diversity in own area

- CMI 504 Assessment: The Rationale For Managing Performance Within Organisations

- Level 7 Unit 03 Assignment: Leading a Strategic Management and Leadership

- LO:01, LO:02 (MSCCO01) Managing Innovation and Change in Computing

- CMI Level 6 Certificate in Professional Management and Leadership

- Financial Accounting: Double-Entry Bookkeeping, Journals, Ledgers, and Trial Balance Preparation

- Assignment 1: Understand and Work with a Wide Range of Stakeholders and Organisational Structures

- CMI 526 Assessment: Principles of Leadership Practice

- Promoting Health, Wellbeing, and Inclusive Care in Health and Social Care Settings

- MID4022 Legal and Ethical Professional Principle in Midwifery

B50EM: Compare and contrast the design principles for wind turbines and tidal turbines. Your review should focus on the sizing: Advanced Mechanics of Materials I Assignment, HWU, UK

| University | Heriot-Watt University (HWU) |

| Subject | B50EM: Advanced Mechanics of Materials |

Part 1 – Review of Energy-Generating Turbine Blade Design

Compare and contrast the design principles for wind turbines and tidal turbines. Your review should focus on the sizing, geometric design, and materials of construction of the blades and should consider the changes in the design dictated by the different types of loading involved.

Part 2: Analytical design

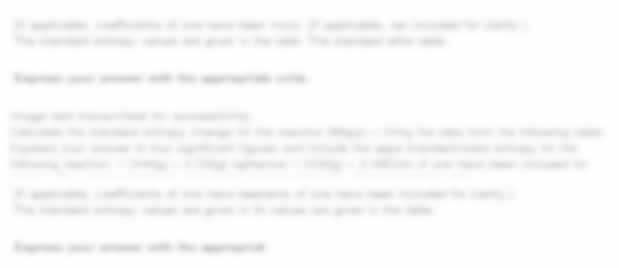

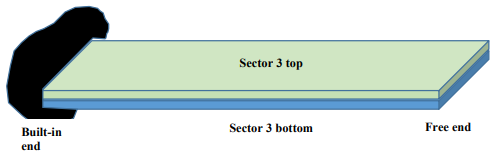

Use two simple models of a blade, assuming it to be a rectangular sheet with either one end or the edge fixed, as illustrated in Figure. Stack the upper and lower surfaces of sector 2 on top of each other to make a single laminate.

Fig. A- Simplified flap-wise model of Sector 2

Fig. B- Simplified edgewise model of Sector 2

Using a [0/45/90/-45]2s lay-up carbon fiber epoxy laminate for the two surfaces stacked together, determine appropriate values of Vf and thickness for the plies to ensure that the composite meets the design deflections under the anticipated peak current loading4 and meets the Tsai-Hill strength criterion with an appropriate factor of safety. Carry out the calculation for each model, and select the lay-up that you consider is the more appropriate of the two.

Part 3: Numerical design

Using the orthotropic modulus from Part 1, build FE model of the simplified configurations you used (Figures A and B) and validate your flapwise and edgewise deflections under the maximum current loading that you used in Part 1. Next, using the material that you designed in Part 1, apply both the edge and end fixities simultaneously. Again, apply the maximum current loading and determine the resulting edgewise and flapwise deflections. Reserve your comments on this result for Part 4.

Part 4: Damage mechanics and fatigue

Using the orthotropic modulus and simplified model from Part 1, but using selected values of mid-surface curvature from Part 2, assess the fatigue life of the blade, assuming an R-ratio of -1, and what you consider to be an appropriate value of stress range. Use the Goodman diagram given in Figure.

Make suggestions for changes to your material design and suggest a full-scale fatigue testing regime for a prototype blade.

Goodman diagram for [0/45/90/-45]2s carbon fibre epoxy laminate

Do You Need Assignment of This Question

UK students, are you struggling with your coursework at Heriot-Watt University (HWU)? We’re here to provide the assistance you need! Our expert team offers reliable help with assignments tailored to your requirements. Dive into the intriguing subject of Advanced Mechanics of Materials and compare the design principles of wind turbines and tidal turbines. Your review will focus on sizing considerations. Pay our experts and witness remarkable improvement in your grades. Trust our professional research paper writing service and excel in your academic journey!